The main production models at our chemical subplant include:

- Corrosive material tank transport vehicles

- Flammable liquid tank transport vehicles

- Corrosive material tank semi-trailers

- Flammable liquid tank semi-trailers

- Chemical liquid transport semi-trailers

- Container transport semi-trailers

- Fuel trucks

- Oil transport trucks

- Oil semi-trailers

- Storage tanks

These vehicles are widely used by hazardous goods transportation companies, large chemical plants, transportation fleets, metallurgy, environmental protection, brewing, food, pharmaceuticals, and storage and transportation enterprises.

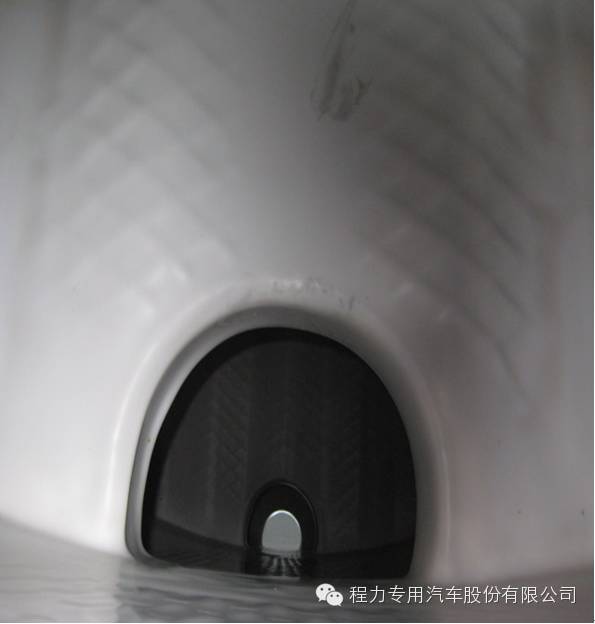

One of the key selling points of our chemical plant is the rotational molding chemical tank. The rotational molding chemical tank is made using a special rotational molding process, where a steel mesh is welded to the inner surface of the tank. Linear polyethylene is used as the material, and through the rotational molding process, the steel plate, steel mesh, and polyethylene are combined into one integrated unit. Our independently developed high-strength wave deflector has obtained a national patent. This rotational molding chemical tank offers excellent advantages such as corrosion resistance, anti-aging, and leak-proof properties, making it an ideal container for chemicals like hydrochloric acid, sulfuric acid, and liquid alkali.

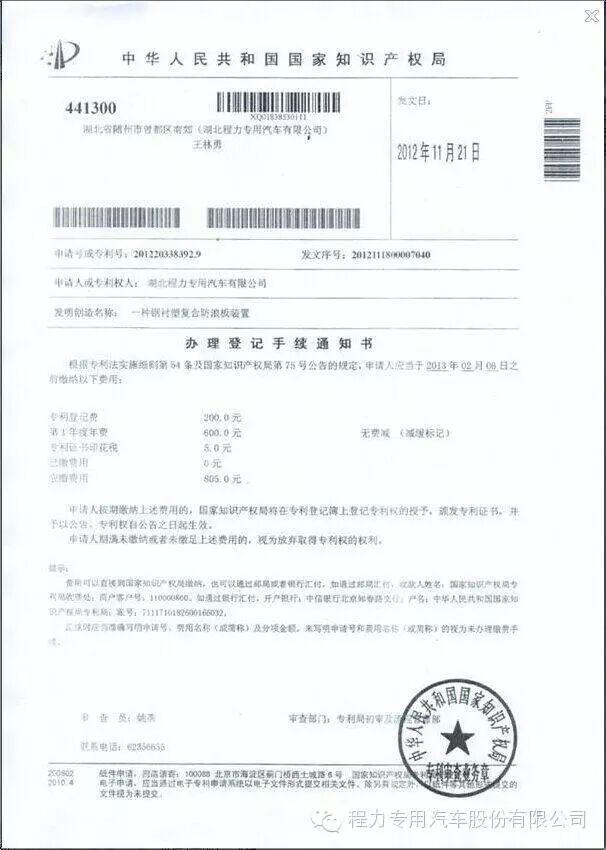

Independently developed high-strength wave deflector

The steel-plastic wave deflector has obtained a national patent.

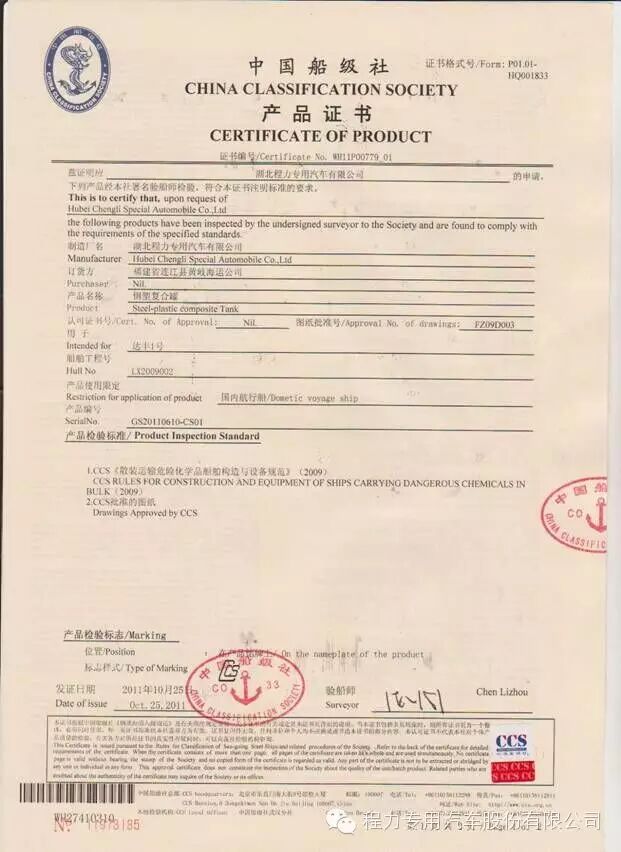

At the same time, we also have marine-lined plastic tanks that have obtained certification from the China Classification Society (CCS).

Our Equipment Advantages:

Special-shaped tank body ring seam automatic welding machine

Hydrostatic expansion head forming machine

9.6 meter long coil

Rotational molding shaker

Lined plastic chemical vehicle

|